Premium Custom Apparel Manufacturing in Greenville, NC

Elevated, customized apparel built for standout brands and team programs—cardigans, varsity & bomber jackets, uniforms, jerseys, all-over prints, and heavyweight polos. Overseas production can mean delays, miscommunication, and limited personalization.

Stop waiting on time zones, language barriers, and unclear expectations.

Tired of working with overseas vendors and having to wait on their timeline just to get the personalization and quality a brand deserves? Overseas production often comes with delays, language barriers, and unclear expectations—especially when details like fabric, fit, and finishing matter.

GMB Custom Apparel is a U.S.-based custom apparel manufacturer in Greenville, North Carolina, serving clients statewide across North Carolina and supporting brands and organizations nationwide. The focus stays on clear communication, defined requirements, and consistent production—so premium custom apparel ideas can move from concept to finished product without the overseas headaches.

This manufacturing service supports premium, highly customized apparel such as cardigan sweaters, sports uniforms, jerseys, hoodies, zip-ups, bonnets, varsity jackets, bomber jackets, all-over prints, premium polos (250–400 GSM), and line jackets.

This manufacturing service supports premium, highly customized apparel such as cardigan sweaters, sports uniforms, jerseys, hoodies, zip-ups, bonnets, varsity jackets, bomber jackets, all-over prints, premium polos (250–400 GSM), and line jackets.

Low MOQs starting at 10 pieces per design/order.

(Some specialty builds or complex processes may require higher minimums based on materials and production method.)

Quick Facts

Turnaround Time

10 Business Days

Rush Available

N/A

Fully Customized

Yes

MOQ

6

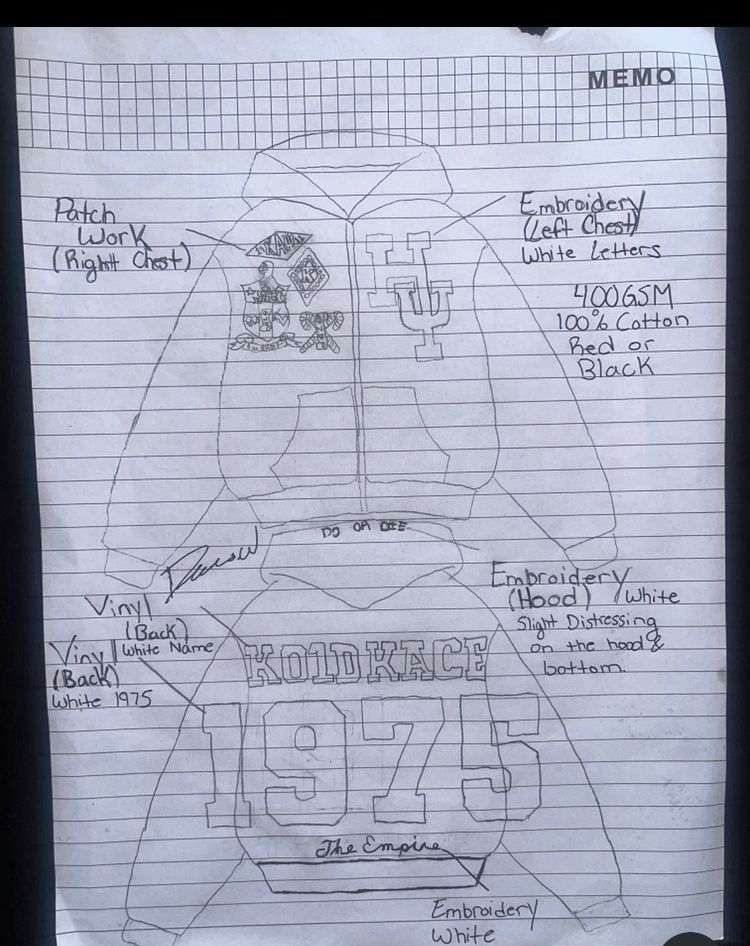

A Clear 1:1 Process to Define Requirements

Every custom apparel project starts with defining requirements the right way. A 1:1 process helps confirm:

- Product type and intended use (teamwear, merch drops, uniforms, outerwear, boutique items)

- Fabric weight and feel (including 250–400 GSM options where applicable)

- Decoration method (embroidery, print, patches, all-over, personalization)

- Placement details (front, back, sleeve, patch zones, numbering locations)

- Sizing and quantity breakdowns

- Production timeline and delivery needs

For clients who want confidence before moving forward,

fabric swatches can be shared

so material, weight, and feel are confirmed upfront—no guessing and no surprises.

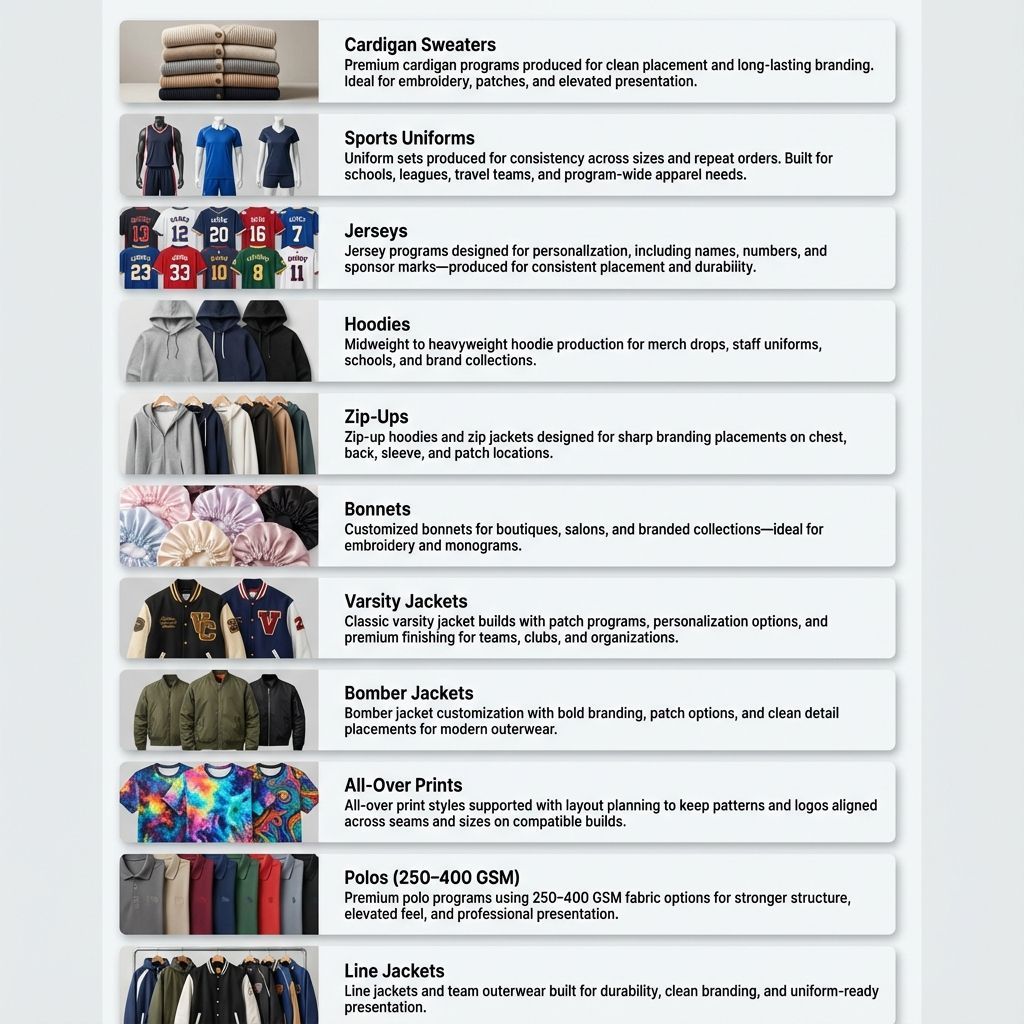

Custom Apparel Categories

Cardigan Sweaters

Premium cardigan programs produced for clean placement and long-lasting branding. Ideal for embroidery, patches, and elevated presentation.

Sports Uniforms

Uniform sets produced for consistency across sizes and repeat orders. Built for schools, leagues, travel teams, and program-wide apparel needs.

Jerseys

Jersey programs designed for personalization, including names, numbers, and sponsor marks—produced for consistent placement and durability.

Hoodies (250–400 GSM)

Midweight to heavyweight hoodie production for merch drops, staff uniforms, schools, and brand collections.

Zip-Ups (250–400 GSM)

Zip-up hoodies and zip jackets designed for sharp branding placements on chest, back, sleeve, and patch locations.

Bonnets

Customized bonnets for boutiques, salons, and branded collections—ideal for embroidery and monograms.

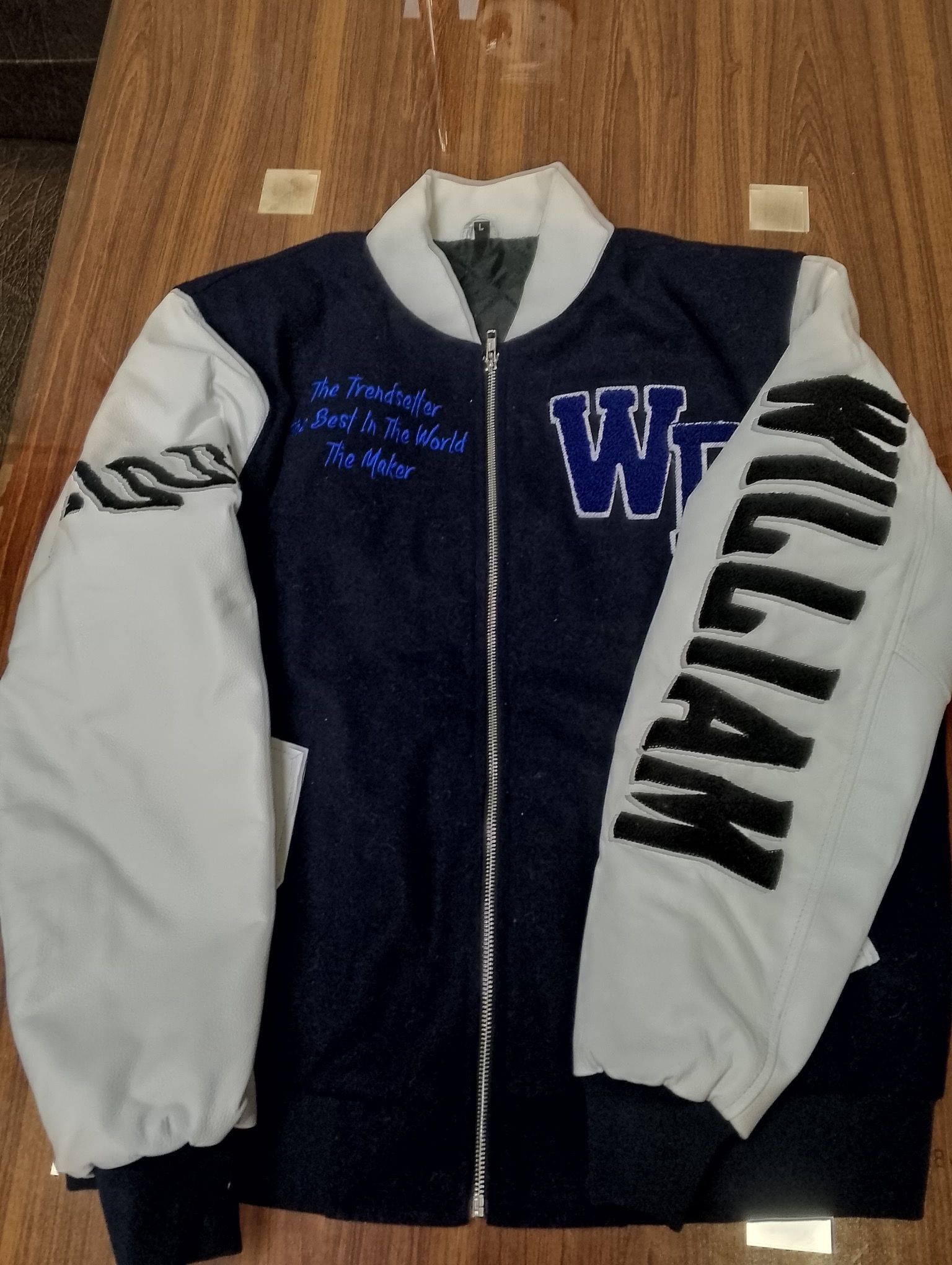

Varsity Jackets

Classic varsity jacket builds with patch programs, personalization options, and premium finishing for teams, clubs, and organizations.

Bomber Jackets

Bomber jacket customization with bold branding, patch options, and clean detail placements for modern outerwear.

All-Over Prints

All-over print styles supported with layout planning to keep patterns and logos aligned across seams and sizes on compatible builds.

Polos

Premium polo programs using 250–400 GSM fabric options for stronger structure, elevated feel, and professional presentation.

Line Jackets

Line jackets and team outerwear built for durability, clean branding, and uniform-ready presentation.

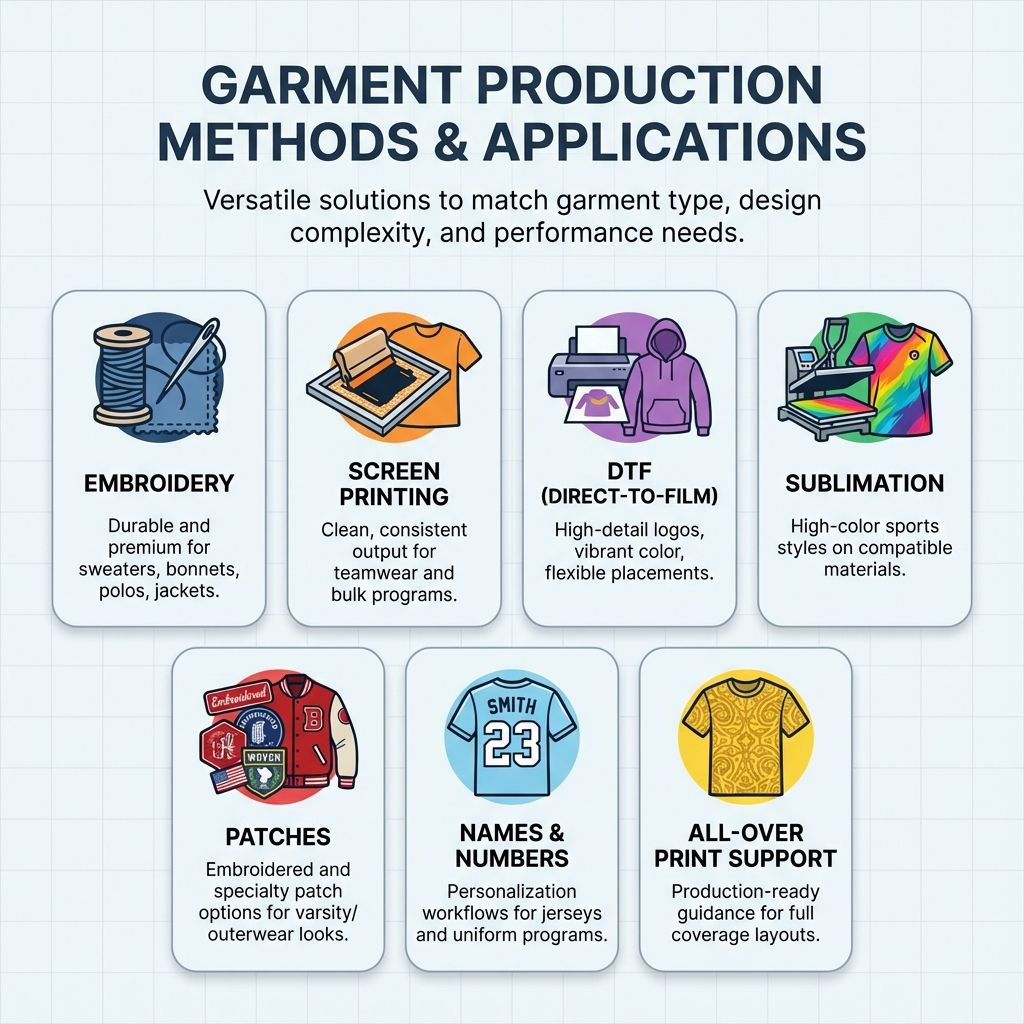

Manufacturing Capabilities for Premium Custom Apparel

Multiple production methods are available to match garment type, design complexity, and performance needs:

- Embroidery (durable and premium for sweaters, bonnets, polos, jackets)

- Screen Printing (clean, consistent output for teamwear and bulk programs)

- DTF (Direct-to-Film) (high-detail logos, vibrant color, flexible placements)

- Sublimation (All over print, high-color sports styles on compatible materials)

- Patches (Chinelle embroidered and specialty patch options for varsity/outerwear looks)

- Names & Numbers (personalization workflows for jerseys and uniform programs)

- All-Over Print Support (production-ready guidance for full coverage layouts)

Premium Fabric Options: 150–400 GSM

Fabric weight matters. 250–400 GSM builds support a premium hand-feel, stronger structure, and elevated appearance—ideal for polos, hoodies, jackets, and cardigan programs.

Fabric and construction can be matched to real-world needs such as corporate uniform programs, teamwear, merch drops, and seasonal collections.

Benefits of 250–400 GSM options include:

- Midweight to heavyweight builds for premium presentation

- More structure and durability for everyday wear

- Consistent branding placement across sizes and repeat runs

All-Over Prints That Look Intentional

All-over prints require planning so logos and patterns stay aligned across seams and sizes. Layout guidance helps reduce surprises and supports clean results.

All-over print support can include:

- Full-coverage layout planning for compatible garments

- Pattern continuity guidance for front, back, and sleeves

- Artwork preparation recommendations based on garment type

Sports Uniforms and Jerseys Built for Consistency

Uniform and jersey programs require accuracy—consistent decoration, repeatable placement, and organized personalization. Programs can be supported with sorting and packaging options to simplify distribution.

Uniform support may include:

- Team set coordination (tops, bottoms, warmups)

- Personalization readiness (names and numbers)

- Durable decoration options based on sport and fabric type

- Sorting for coaches, managers, or departments

A Simple Premium Manufacturing Process

Intake & Requirements

Styles, fabric goals, quantities, sizes, deadlines, and program needs.

Artwork & Proofing

Production-ready layouts prepared for approval before production begins.

Sourcing & Planning

Recommendations matched to fabric weight, durability, fit, and availability.

Production & Quality Checks

Repeatable steps focused on consistency and clean finishing.

Packaging & Delivery

Local pickup options across North Carolina (where applicable) and shipping support nationwide.

Packaging and Program Support

Manufacturing-style programs often require organization and presentation. Packaging support can include:

- Size sorting for teams and departments

- Player/employee distribution sorting

- Fold, bag, and label options

- Kitting support for multi-location programs

- Drop-ready packaging options for brand releases

Why Choose GMB Custom Apparel for Premium Customized ManufacturingA